Ultra-precision Machining Technologies

Thin Leaf Springs

We provide comprehensive support to our customers, starting from analysis and design of various spring properties such as behavior analysis and load and stress analysis using FEM analysis, precision machining technologies such as pressing, heat treatment and shot peening to shape the design, and technologies to evaluate and analyze products.

Features

- We can shorten the development period using abundant know-how and experience as a manufacturer specialized in springs, and product design that integrates FEM analysis.

- Using various heat-treat furnaces, we can provide integrated production from pressing, cleaning, to heat treatment. Facilities owned: Quenching and tempering furnace, austempering furnace, vacuum furnace, continuous hydrogen atmosphere furnace, etc.

- We can treat products with strict product cleanliness. Facilities owned: Clean room, hydrocarbon washing machine, pure water washing machine, cleanliness evaluation facility.

- We can handle trial production of several units to mass production of several millions of units per month.

- We acquired ISO 9000 Series and ISO 14001 certifications, and have received high evaluation from many automobile and electronic manufacturers especially on our quality. We can provide comprehensive support from development and design, trial production, to mass production.

- We can provide thin leaf spring assemblies utilizing laser welding, brazing, adhesive, and adhesive technology.

Possible Range of Production

Material:

Spring steel, stainless steel, phosphor bronze, maraging steel, etc.

Plate thickness:

0.05mm to 3.5mm

Forming technique:

Press working (punching, cold forging, bending, raising, etc.)

In particular, we are focusing on press forming with progressive die that combines several of those processing methods.

*Contact us for details.

Application Examples

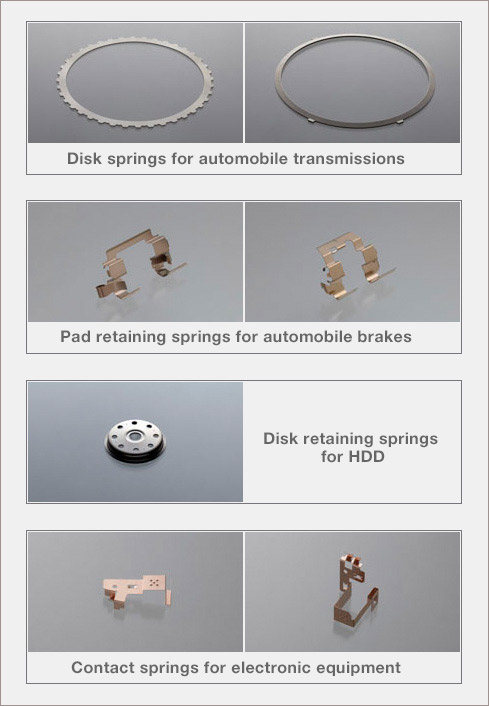

- Disk springs for automobile transmissions

- Pad retaining springs for automobile brakes

- Disk retaining springs for HDD

- Contact springs for electronic equipment

- Springs for double valve seat

- Element retaining springs for hybrid and electric cars

Contact

Precision Stamped Products

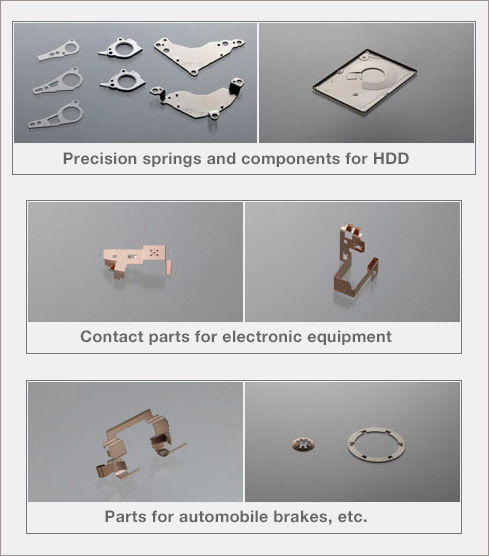

We provide precision springs and components that are indispensable for automobiles, electronic equipment, and home appliances using press forming. Especially for products manufactured in large quantity with heavy use of machines, you can reduce cost substantially by using press working.

Features

- Molds are manufactured at dedicated mold plants.

- For products that require mechanical characteristics such as spring property and rigidity, we can support product design with FEM analysis technology.

- Since we have equipment such as barrel equipment in addition to press equipment, cleaning equipment, and various heat-treatment furnaces, we can respond to various demands.

Press equipment: 20Ton, 40Ton, 60Ton, 80Ton, 160Ton, 250Ton, 300Ton press

Barrel equipment: Rotary barrel, centrifugal barrel, roll flow barrel

Heat-treatment furnace: Atmosphere quenching furnace, tempering furnace, vacuum furnace, austempering furnace, continuous hydrogen atmosphere furnace

Cleaning equipment: Hydrocarbon washing machine, pure water washing machine

Other: Shot peening, honing - We can support products with strict product cleanliness by making them in a clean room.

- We can handle trial production of several units to mass production of several millions of units per month.

- We acquired ISO 9000 Series and ISO 14001 certifications, and have received high evaluation from many automobile and electronic manufacturers especially on our quality. We can provide comprehensive support from development and design, trial production, to mass production.

- We can provide assemblies utilizing laser welding, brazing, adhesive, and adhesive technology.

Possible Range of Production

Material:

Common steel, special steel for springs, stainless, aluminum, brass, phosphor bronze, maraging steel, silicon steel, etc.

Plate thickness:

0.05mm to 3.5mm

Supported press technology:

Punching, cold forging, bending, raising, etc.

In particular, we are focusing on press forming with progressive die that combines several of those processing methods.

*Contact us for details.

Application Examples

- Precision springs and components for HDD (parts for motors, mechanical parts)

- Contact parts for electronic equipment

- Parts for automobile transmissions and brakes